The engineering challenge is straightforward: how do you eliminate multiple fabrication steps, reduce material waste, and improve structural performance simultaneously? The answer lies in the precise technical execution of weldment-to-casting conversions, a manufacturing strategy that consistently delivers 20-50% cost savings while enhancing component reliability.

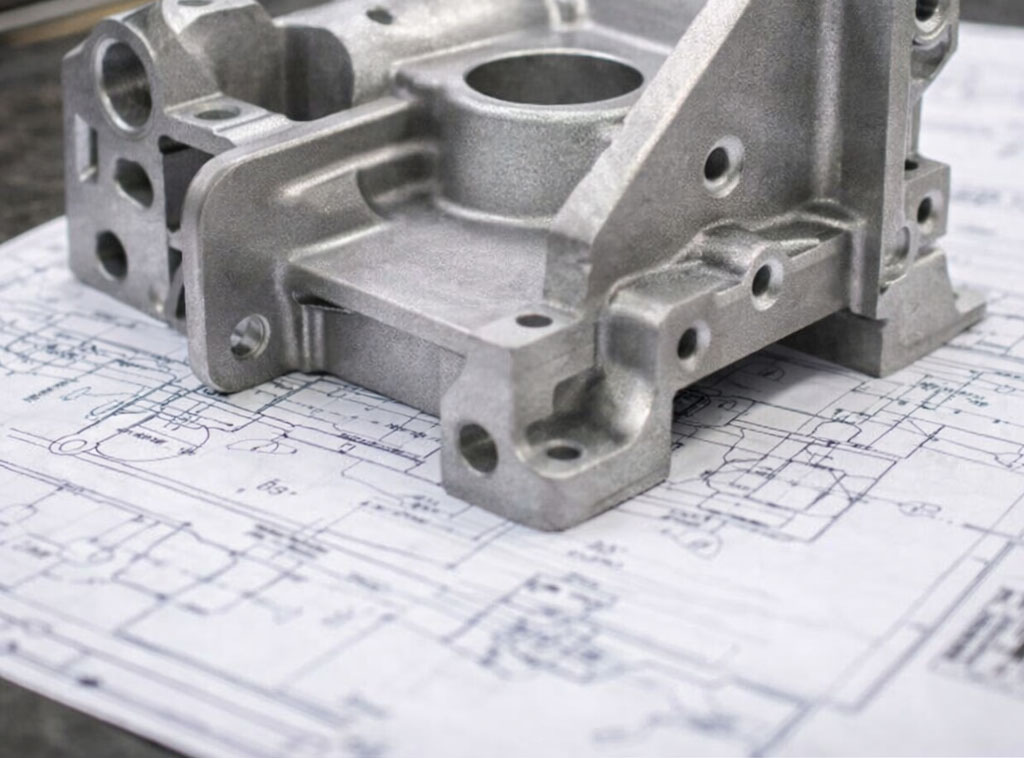

At CaneKast, we’ve engineered these conversions across diverse industrial applications, and the results follow predictable technical patterns. When a multi-piece weldment transforms into a single aluminum casting, three fundamental engineering advantages emerge: elimination of heat-affected zones, precise dimensional control across the entire component, and optimized material distribution based on stress analysis rather than fabrication constraints.

Critical Design Parameters: Parting Line Engineering

The technical foundation of any successful conversion begins with parting line optimization. Unlike weldment design, where joint locations are dictated by fabrication sequence, casting parting lines must be engineered to optimize aluminum flow characteristics and solidification patterns.

The engineering approach starts with comprehensive stress analysis of the original weldment. You’ll need to identify load paths, stress concentrations at weld joints, and areas where the multi-piece design creates unnecessary material thickness. This analysis directly informs parting line placement; positioning the parting plane to minimize turbulent flow while ensuring critical load-bearing sections solidify with optimal grain structure.

Aluminum’s fluidity index provides significant design flexibility, but this advantage only materializes with precise parting line engineering. We use computational fluid dynamics modeling to predict fill patterns and identify potential turbulence zones that could create porosity in critical areas.

The technical reality: proper parting line placement can eliminate 60-80% of secondary machining operations compared to the original weldment, while achieving superior dimensional consistency across all critical surfaces.

Solidification Engineering: Optimizing Microstructure Distribution

Aluminum’s solidification characteristics enable engineering approaches impossible with weldments. Section thickness directly correlates with cooling rate, which determines grain structure and mechanical properties. This relationship allows us to engineer varying section thicknesses across a single casting to optimize strength where needed while minimizing weight.

The technical approach leverages aluminum’s unique property where thinner sections with ribs or similar often exhibit higher yield strength than thicker sections due to faster cooling rates and finer grain structure. This contradicts steel design principles but opens significant optimization opportunities.

Computer modeling reveals solidification sequences and identifies where directional solidification can be controlled through strategic placement of chills and risers. For components with multiple load paths, the casting geometry can be engineered so critical stress-bearing sections solidify last, ensuring sound material in high-stress zones.

Section modulus calculations demonstrate how aluminum castings achieve equivalent or superior stiffness compared to steel weldments at 35% of the weight. This isn’t just material substitution, it’s structural optimization enabled by casting’s geometric flexibility.

Integrated Feature Design: Eliminating Assembly Operations

The technical advantage of single-piece construction extends beyond simple consolidation. Aluminum casting enables integration of features that would require separate operations in weldment fabrication: bosses, mounting tabs, internal passages, and complex contours become integral casting features rather than secondary additions.

We can aid your engineering process to evaluate each weldment component for integration potential. Features requiring precise positional relationships, critical in machinery components, achieve superior accuracy when cast as unified geometry rather than assembled from separate pieces. Accumulated tolerance stack-up, a persistent challenge in multi-piece weldments, becomes irrelevant.

Cored passages represent a particular technical strength. Where weldments might require drilled holes or fabricated tubes, aluminum castings can incorporate complex internal geometries as integral features. We’ve successfully cast components with intersecting passages, internal galleries, and complex mounting interfaces that would be prohibitively expensive to machine or fabricate.

Stress Concentration Engineering: Radius Optimization

The most significant technical advantage in weldment conversion involves stress concentration elimination. Welded joints create geometric discontinuities, sharp transitions where stress concentrations reduce fatigue life by 300-400% compared to smooth transitions.

Aluminum casting inherently produces filleted transitions at all intersections. Our engineering approach optimizes these radii based on stress analysis rather than accepting arbitrary fabrication constraints.

We engineer these transitions using finite element analysis to determine optimal radius sizes for each geometric junction. The technical result: components that demonstrate 40-60% longer fatigue life compared to equivalent weldments, even when subjected to identical loading conditions.

Thermal Management Through Material Engineering

Aluminum’s thermal conductivity thermal management opportunities unavailable in steel weldments. For components experiencing thermal cycling, you can engineer variable section thickness to control heat dissipation patterns and minimize thermal stress.

Manufacturing Process Integration

The technical execution requires coordination between casting process parameters and final component requirements.

Our process engineering integrates casting parameters with downstream machining requirements. As-cast surfaces achieve <400 RMS finishes in most geometries, eliminating preliminary machining operations. Where precision surfaces are required, we cast with stock removal, ensuring consistent machining parameters across production runs.

The measurable results consistently demonstrate the technical validity of this approach: a multi-piece weldment conversion delivered 35% cost reduction, eliminated weeks of lead time, and improved component reliability through superior stress distribution and thermal management.

For manufacturing engineers evaluating similar opportunities, the technical framework provides predictable pathways to significant cost and performance improvements. The key lies in rigorous engineering analysis that optimizes aluminum casting’s unique capabilities rather than simply replicating weldment geometry in different material.